Vortex flow measurement technology is used to measure flow of utilities like compressed air, steam & even fuel oil. Vortex meters are reliable & most accurate flow measurement technology available & widely accepted across the industries.

We are associated with Omicron U.S.to bring this flow measurement technology for various flow measurement application. Vortex flow meters working principle is von Karman’s effect principle which is based upon viscosity & velocity of fluid media. Vortex flow meters are used for domestic as well as industrial flow application wherever high accuracy is required.

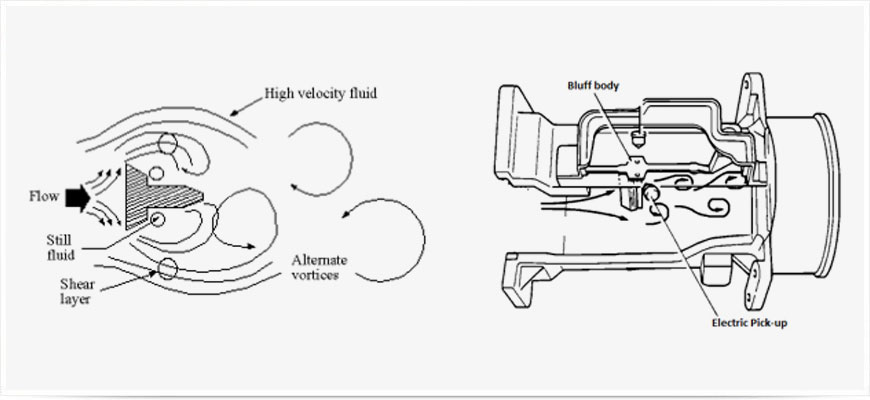

Von Karman principle is stated as below.

“When a media moves in a direction & hits directly to a bluff body, vortices are generated. The frequency of vortices is directly proportional to the flow rate of media.”

This frequency of vortices is then picked up by a coil pick-up placed after shredded rod or bluff body, when vortices hit the pickup.

Benefits & Features

- No moving parts

- High Accuracy as high as ± 0.5 %

- Flow range 10:1

- Low pressure drop

- Pressure & temperature compensation available as optional.

We have both integral type & remote type sensors option available as far as mounting is considered. The sensor selection is generally depend upon the application & site conditions. We recommend you to take our expert advice before making selection of appropriate sensor.

Technical Specification

- Accuracy: ± 0.5%

- Damping Time 0.2~100s selectable

- Analog Output: 0-10 VDC/4~20mA.

- Protection Class: For electronic box IP65 (outdoor) or IP 67 (optional)

- Lining Material: Rubber, PTFE, Polyurethane, PFA

- Sensor Material: AISI Stainless steel

- Measuring Range 10:1, flow rate ≤12m/s (39ft/s)

- Power Supply: 24 VAC

- Structure Type: Integral type, remote type, submersible type